Specialized cleaning and maintenance for carwash water reclamation systems throughout Western North Carolina

Advanced Carwash System Maintenance

Carwash facilities depend on properly functioning water management systems—including reclamation pits, separators, and associated plumbing—to operate efficiently and meet environmental regulations. These specialized systems require regular maintenance to prevent costly downtime, ensure water quality, and maintain compliance with discharge requirements.

Viking Environmental and Septic Services provides professional carwash maintenance solutions utilizing our advanced Vactor 2100+ equipment. This powerful combination of vacuum technology and high-pressure water jetting delivers superior cleaning for all types of carwash water management systems throughout Western North Carolina.

The Carwash System Maintenance Challenge

Critical Water Management Components

Modern carwash facilities contain specialized water handling systems:

- Settlement pits that collect solids and debris

- Oil/water separators that prevent petroleum discharge

- Water reclamation systems for reuse efficiency

- Underground tanks for water collection and treatment

- Filtration systems for water quality management

- Collection troughs and drains throughout the facility

- Complex plumbing networks connecting system components

Maintenance Imperatives

These systems require professional service for several reasons:

- Heavy sediment accumulation from vehicle washing

- Grease and oil buildup requiring proper removal

- Scale formation in pipes and equipment

- Biofilm development affecting water quality

- System performance degradation without regular service

- Environmental compliance requirements for discharge

- Manufacturer maintenance specifications for warranty protection

Our Comprehensive Carwash Maintenance Services

Settlement Pit Cleaning

We restore proper function to critical collection systems:

- Complete sediment removal from pit bottoms

- Sidewall cleaning to eliminate buildup

- Grease and oil removal from surfaces

- Proper waste classification and disposal

- Structure inspection during cleaning

- Function verification after service

- Documentation of service for compliance

Oil/Water Separator Maintenance

Our thorough service restores separator efficiency:

- Removal of accumulated oils from separation chambers

- Sediment extraction from settlement areas

- Cleaning of baffles and weirs for proper function

- Component inspection during maintenance

- Clean water testing after service

- System adjustment when needed

- Performance verification before completion

Water Reclamation System Service

We maintain these complex water recycling systems:

- Tank cleaning to remove solids buildup

- Filter media maintenance for optimal performance

- Distribution system cleaning to prevent clogging

- Treatment system component service

- Pump intake clearing for reliable operation

- Control system validation after cleaning

- Complete system evaluation during service

Drain and Trench Cleaning

We clear critical water collection pathways:

- High-pressure water jetting of drain lines

- Trench and trough cleaning throughout facility

- Grate and cover cleaning for proper flow

- Blockage removal from drainage systems

- Root intrusion clearing where applicable

- Flow testing after service completion

- Preventive maintenance recommendations

The Vactor 2100+ Advantage for Carwash Maintenance

Superior Cleaning Power

Our advanced equipment delivers exceptional results:

- Powerful vacuum capability for complete material removal

- High-pressure water jetting for stubborn deposits

- Simultaneous vacuum and jetting for efficient cleaning

- Extended reach capability for difficult access areas

- Large debris capacity for complete servicing

- Advanced separation technology for waste management

- Versatile tool attachments for specialized cleaning

Efficient Service Delivery

Our equipment and expertise minimize disruption:

- Rapid system cleaning reducing downtime

- Complete service in a single visit for most facilities

- Systematic approach addressing all components

- Independent operation requiring minimal facility support

- Self-contained units bringing all necessary resources

- Efficient material handling during service

- Quick system restoration after maintenance

Benefits of Professional Vactor Carwash Maintenance

Operational Improvements

Regular maintenance enhances carwash performance:

- Restored water flow capacity throughout systems

- Reduced equipment strain from proper drainage

- Improved water quality for better wash results

- Consistent water pressure from clean distribution systems

- Enhanced reclaim water clarity for reuse applications

- Extended equipment lifespan through proper care

- Reduced chemical consumption with clean systems

Environmental Compliance

Our services support regulatory requirements:

- Proper handling of collected materials

- Reduced discharge contaminants through system efficiency

- Documentation of maintenance for compliance records

- Waste disposal following environmental regulations

- Prevention of unauthorized discharges from overflows

- Stormwater compliance support for runoff management

- Reduced water consumption through efficient reclamation

Cost Reduction and Efficiency

Professional maintenance proves economical:

- Prevention of costly emergency service needs

- Reduced water consumption costs through efficiency

- Lower sewer charges from proper pretreatment

- Extended equipment life reducing replacement costs

- Minimized chemical usage through proper system function

- Reduced energy costs from efficient pumping

- Decreased downtime from system failures

Customer Experience Enhancement

Well-maintained systems improve service quality:

- Consistent water quality for better cleaning results

- Reliable equipment operation preventing customer delays

- Elimination of odors from stagnant water or biofilm

- Improved pressure consistency for wash performance

- Reduced spotting from properly filtered water

- More effective soap and chemical action in clean systems

- Overall enhanced wash quality and customer satisfaction

Types of Carwash Facilities We Service

Tunnel Carwash Operations

Complete maintenance for high-volume facilities:

- Conveyor tunnel systems with multiple washing stages

- High-production facilities with substantial water usage

- High-capacity water reclamation systems

- Complex drainage networks throughout tunnel length

- Multiple settlement pit configurations

- Industrial-scale separation systems

- Central vacuum system drainage

Automatic Bay Facilities

Tailored service for touchless and friction automatics:

- Touchless automatic systems with high-pressure water

- Friction wash automatics with different waste profiles

- Stand-alone reclamation systems

- Individual bay drainage networks

- Equipment room plumbing systems

- Bay floor drains and collection trenches

- Multiple-bay facilities with shared water systems

Self-Service Carwashes

Specialized maintenance for self-service operations:

- Multi-bay self-service facilities

- Central equipment room drainage

- Coin-operated systems with unique configurations

- Simpler reclamation designs

- Common settlement pits for multiple bays

- Pressure washer drainage systems

- Centralized or distributed water management

Fleet Washing Facilities

Supporting commercial vehicle washing operations:

- Commercial truck washing facilities

- Bus and transit fleet washing systems

- Heavy equipment washing operations

- High-solids handling systems

- Large-capacity settlement designs

- Enhanced oil separation requirements

- Industrial water reclamation equipment

The Viking Carwash Maintenance Process

1. Comprehensive System Assessment

We begin with a thorough evaluation:

- Initial inspection of all water management components

- Assessment of sediment and waste accumulation

- Evaluation of system performance

- Identification of maintenance priorities

- Review of previous service records

- Development of appropriate cleaning approach

- Discussion of schedule to minimize operational impact

2. Systematic Cleaning Protocol

Our experienced team performs thorough maintenance:

- Strategic equipment positioning for optimal access

- Systematic cleaning following best practices

- Appropriate technique selection for each component

- Thorough material removal from all structures

- Proper waste containment during operation

- Continuous monitoring of system condition

- Sequential cleaning to maintain system operation when possible

3. Component Inspection and Evaluation

During cleaning, we provide valuable system assessment:

- Structural inspection of pits and tanks

- Evaluation of separator component condition

- Identification of worn or damaged elements

- Assessment of plumbing system integrity

- Examination of filtration system efficiency

- Review of overall system design effectiveness

- Documentation of findings for future planning

4. Verification and Documentation

We confirm results and provide complete information:

- Post-cleaning inspection of serviced components

- Flow testing of drainage systems

- Documentation of material removed

- Notation of any system deficiencies discovered

- Before and after photos when helpful

- Recommendations for repairs if needed

- Maintenance records for compliance requirements

5. Responsible Waste Management

We handle all collected materials properly:

- Appropriate separation of water and solids

- Proper classification of waste materials

- Transportation to authorized disposal facilities

- Compliance with all environmental regulations

- Documentation of disposal for records

- Recycling when appropriate and available

- Minimized environmental impact throughout process

Why Choose Viking for Carwash Maintenance

Specialized Carwash Knowledge

Our team brings expertise specific to carwash systems:

- Understanding of carwash water management design

- Knowledge of common system configurations

- Recognition of unique carwash operation needs

- Experience with various reclamation technologies

- Familiarity with manufacturer specifications

- Understanding of water chemistry factors

- Awareness of maintenance impact on operations

Advanced Equipment Investment

Our commitment to quality is reflected in our equipment:

- State-of-the-art Vactor 2100+ combination units

- Specialized nozzles and attachments for carwash applications

- Extended reach capability for difficult access

- Appropriate capacity for complete service

- Self-contained operation requiring minimal facility resources

- Advanced filtration for environmental protection

- Maximum material removal capability

Industry-Specific Experience

Our team's background ensures superior service:

- Specialized training in water reclamation systems

- Experience across diverse carwash facility types

- Knowledge of proper cleaning techniques for components

- Understanding of water quality requirements

- Problem identification skills for system issues

- Awareness of operational impact considerations

- Preventive maintenance perspective

Comprehensive Service Approach

We provide value beyond basic cleaning:

- Complete system service not just problem areas

- Identification of developing issues before failure

- Recommendations for system improvements

- Maintenance scheduling assistance

- Documentation for regulatory compliance

- Integration with other environmental services

- Long-term partnership approach

Our Service Area

Our Service Area

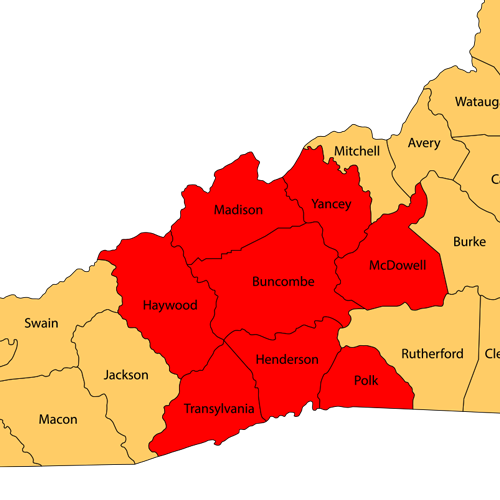

We provide Professional Vactor Carwash Maintenance throughout Western North Carolina, including:

- Buncombe County, NC - Serving Asheville, Arden, Black Mountain, Candler, Fairview, Leicester, Swannanoa, Weaverville, and Woodfin

- Haywood County, NC - Serving Waynesville, Maggie Valley, Canton, Clyde, Lake Junaluska, and Hazelwood

- Henderson County, NC - Serving Hendersonville, Fletcher, Etowah, Flat Rock, Horse Shoe, Mills River, and Mountain Home

- Madison County, NC - Serving Marshall, Mars Hill, Hot Springs, Spring Creek, and surrounding communities

- McDowell County, NC - Serving Old Fort, Marion, Nebo, Pleasant Gardens, and surrounding areas

- Polk County, NC - Serving Columbus, Tryon, Mill Spring, Saluda, Green Creek, and Lynn

- Transylvania County, NC - Serving Brevard, Pisgah Forest, Rosman, Cedar Mountain, and Lake Toxaway

- Yancey County, NC - Serving Burnsville, Micaville, Cane River, Green Mountain, Swiss, and Price Creek

Signs Your Carwash System Needs Maintenance

Performance Indicators

These operational issues suggest maintenance is needed:

- Slow draining wash bays or tunnels

- Reduced water pressure in reclaim systems

- Visible sediment in reclaimed water

- Water backing up in floor drains

- Equipment struggling to maintain pressure

- Sensor malfunctions from sediment interference

- Water quality issues affecting wash results

Physical Signs

These observable conditions indicate service is required:

- Visible sludge buildup in pits or tanks

- Oil sheen on water surfaces in collection areas

- Odors from water management systems

- Overflow or bypassing of treatment components

- Visible biofilm or algae growth

- Standing water in areas that should drain

- Sediment visible at access points

Maintenance Timing

These schedule factors often trigger cleaning needs:

- Manufacturer-recommended service intervals approaching

- Extended period since last professional cleaning

- Following busy season with high wash volume

- Prior to major equipment service or upgrades

- Before health department or environmental inspections

- Seasonal preparation before winter or summer peaks

- After nearby construction that may have affected drainage

Frequently Asked Questions About Carwash Maintenance

How often should carwash water systems be cleaned?

Cleaning frequency depends on wash volume, system design, and local conditions. Most high-volume tunnel operations benefit from quarterly maintenance of settlement pits and separators, while self-service facilities might require bi-annual service. Reclamation systems typically need attention every 3-6 months for optimal performance. We can help establish an appropriate maintenance schedule based on your specific facility and conditions.

Can you perform maintenance while the carwash remains operational?

In many cases, yes. For facilities with multiple bays or dual settlement systems, we can often service one portion while keeping others operational. For tunnel operations, we typically recommend scheduling during off-hours or slower business periods for complete service. Our team works efficiently to minimize downtime, and we can develop a service plan that limits operational impact.

How long does a typical carwash maintenance service take?

Service time varies based on system size and condition. A standard self-service facility with 4-6 bays might require 4-6 hours for complete maintenance. Larger tunnel operations with extensive reclamation systems typically need 6-8 hours. Facilities with substantial sediment accumulation or systems that haven't been serviced regularly may require additional time.

Will your service affect my water recycling system's function?

Our maintenance improves recycling system function by removing accumulated sediment and contaminants that impair efficiency. We understand the specific requirements of different reclamation technologies and adjust our approach accordingly. Following service, these systems typically operate more efficiently with improved water quality. We ensure all components are properly reassembled and functioning before completion.

Do you provide emergency service for carwash drainage problems?

Yes, we offer emergency response for urgent situations such as complete drain blockages, system overflows, or failures preventing operation. Our team prioritizes emergency calls and works to respond as quickly as possible throughout our service area, typically within 24 hours and often same-day for critical situations in the Asheville metro area.

Schedule Your Carwash Maintenance Service Today

Whether you operate a high-volume tunnel, automatic bay system, or self-service facility, Viking Environmental and Septic Services provides professional Vactor maintenance solutions for all carwash water management systems throughout Western North Carolina.

Call (828) 782-0003 or fill out our online form today to discuss your carwash maintenance needs or to schedule service.

Viking Environmental and Septic Services: Exceptional environmental services done right the first time. Proudly serving Buncombe, Haywood, Henderson, Madison, McDowell, Transylvania, Polk, and Yancey Counties with professional carwash maintenance services.